The new Studio3 frame

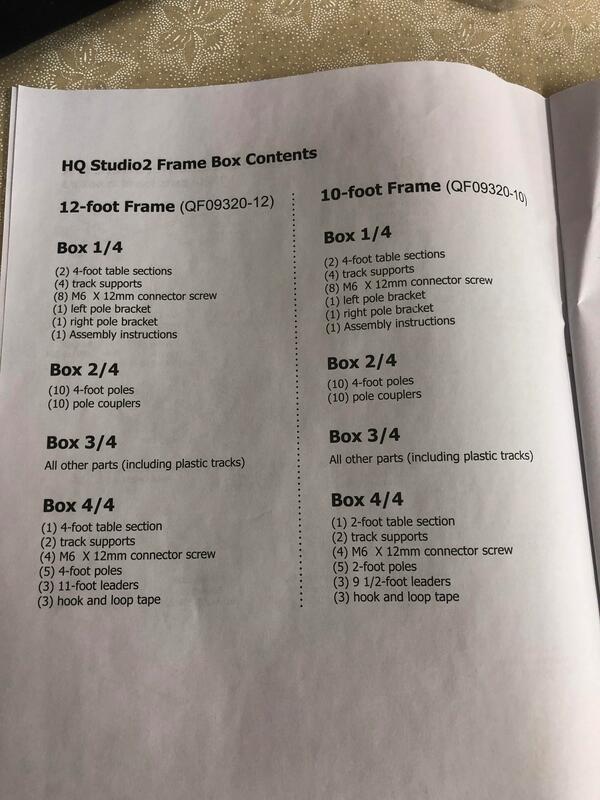

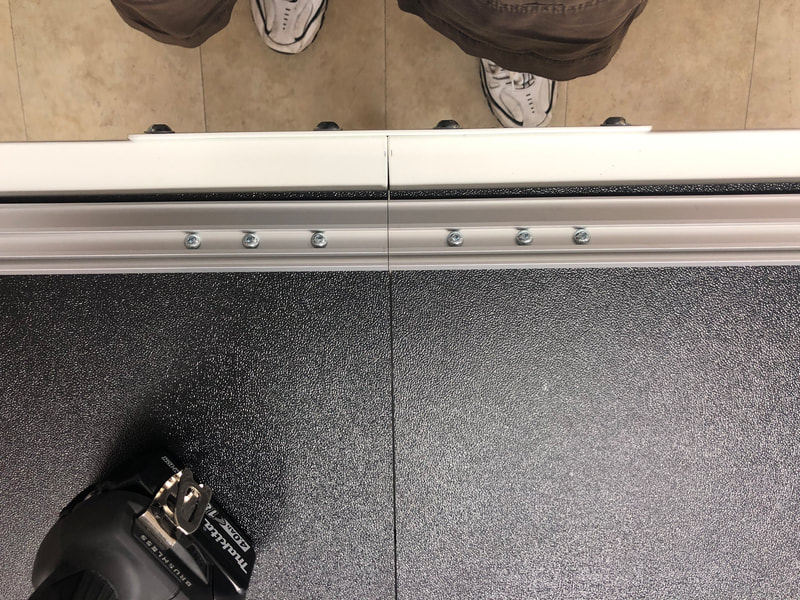

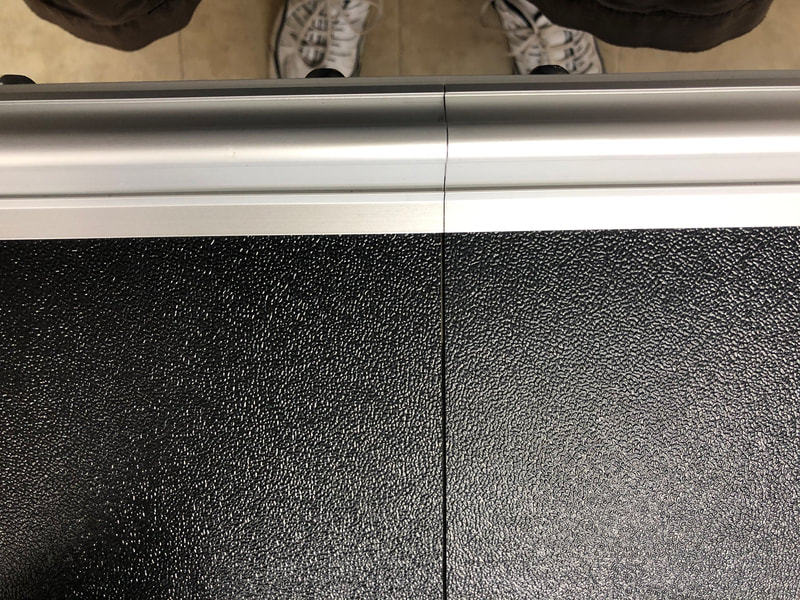

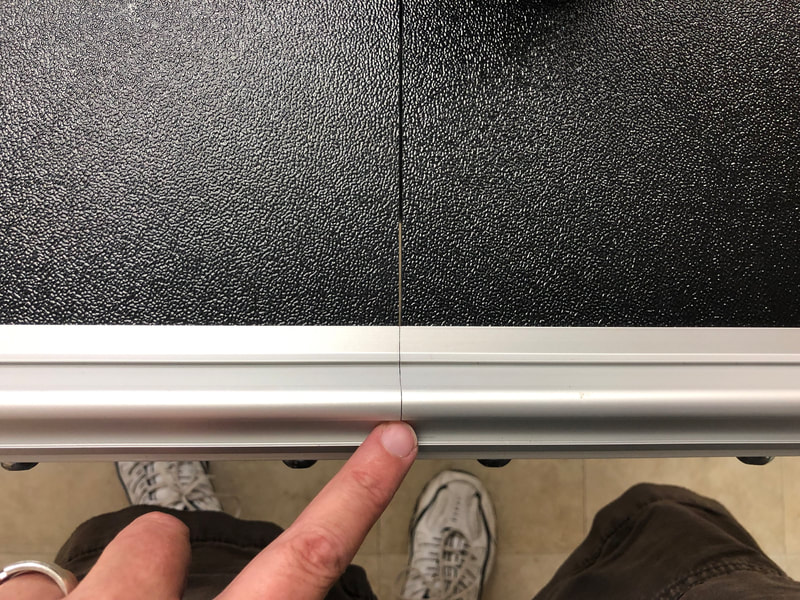

As of May 2023, Handi Quilter is no longer shipping the Studio2 frame. The Studio2 added the adjustable sidearms to the original Studio frame which is an available upgrade to existing frames. The Studio3 frame has several MAJOR changes that make some accessories like the extra hand wheels and the Secret Drawers incompatible with the Studio2 versions.

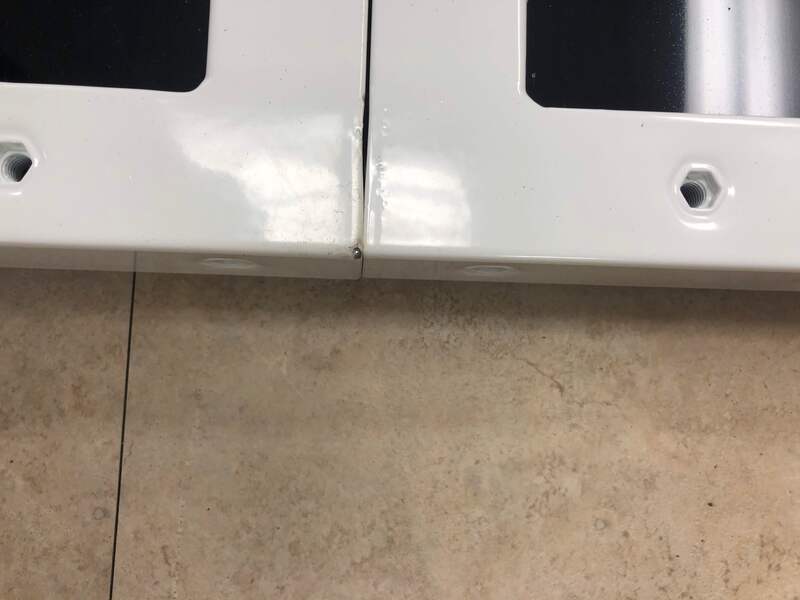

The 'Picture Book' below showing the Studio2 installation still provides many details that can be helpful when setting up the Studio2 or Gallery2 frames. This section will attempt to identify some of the differences and try to clarify issues that lead arose during our first experience with the installation process.

|

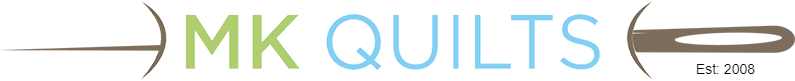

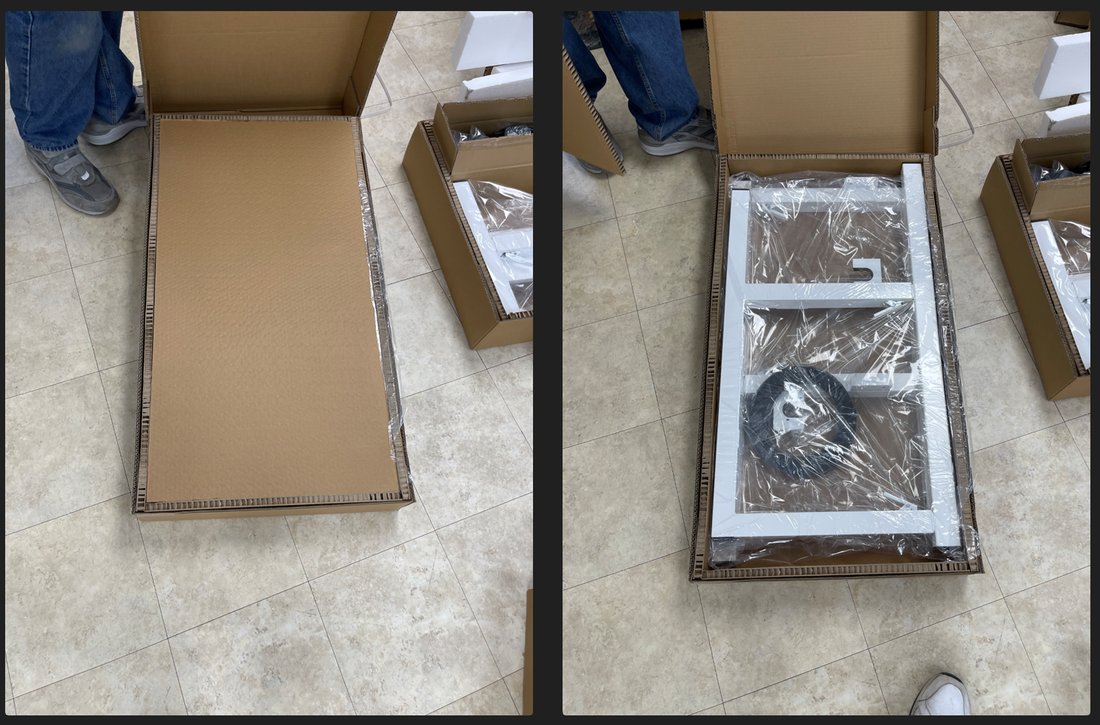

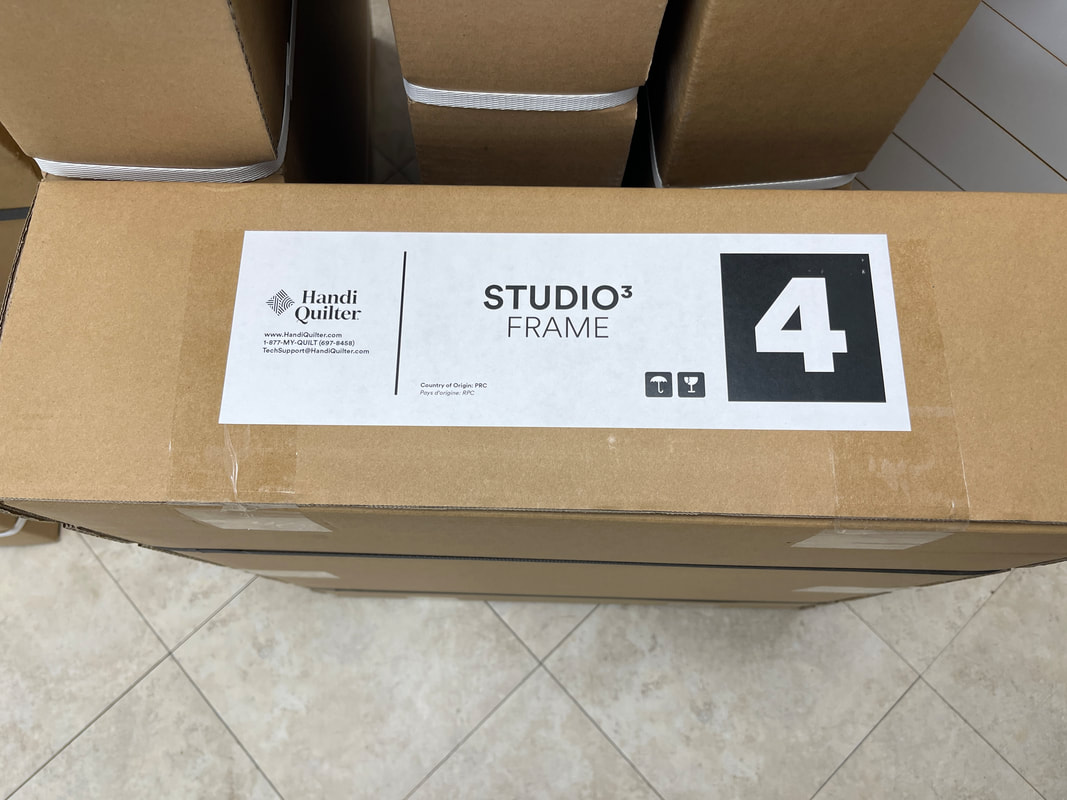

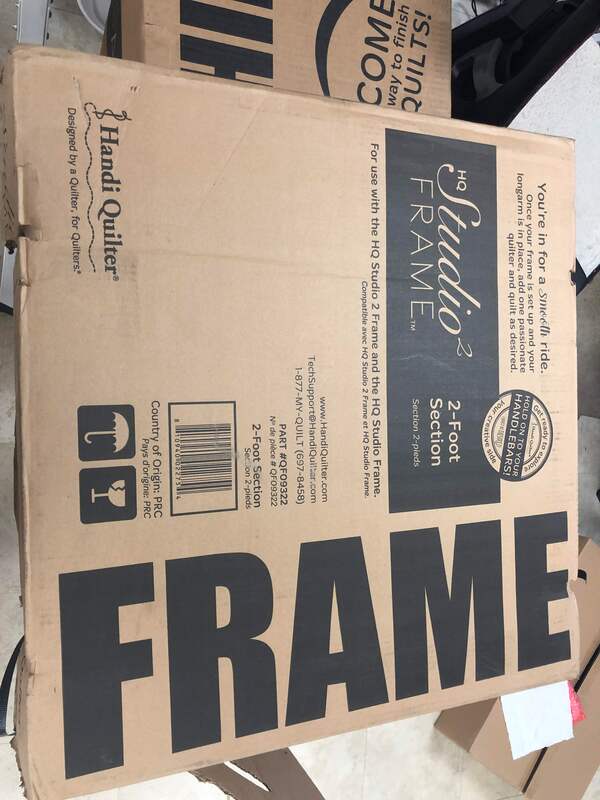

Meet the new Studio3 frame - More Boxes

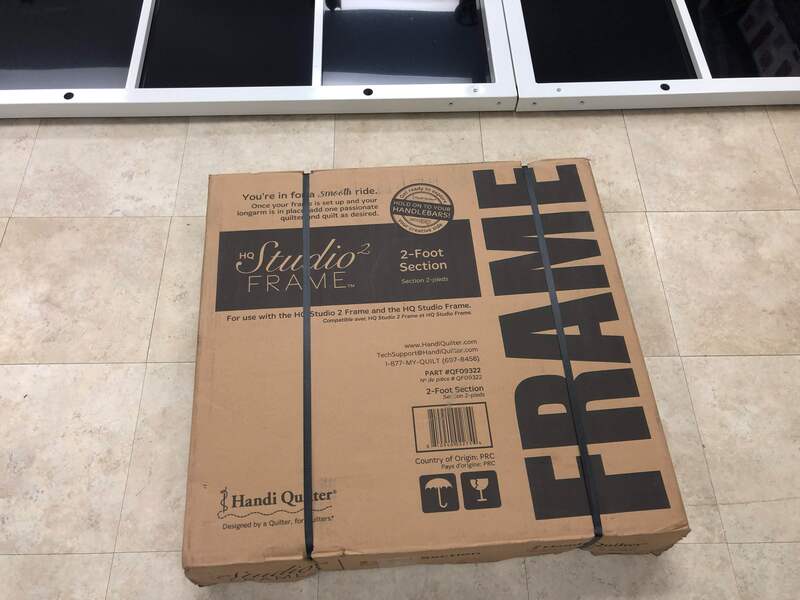

This may not seem important. However, one of the most challenging issues we have had since the Covid years has been with shipping the Studio2 frame. Many of the boxes exceeded 50 pounds and would be damaged in route to the customer. This is the 10ft configuration. The 12ft configuration will have a different Box 1 and likely include a third #2 box and not include the #6 box. This will make more sense as you see it unboxed.

|

|

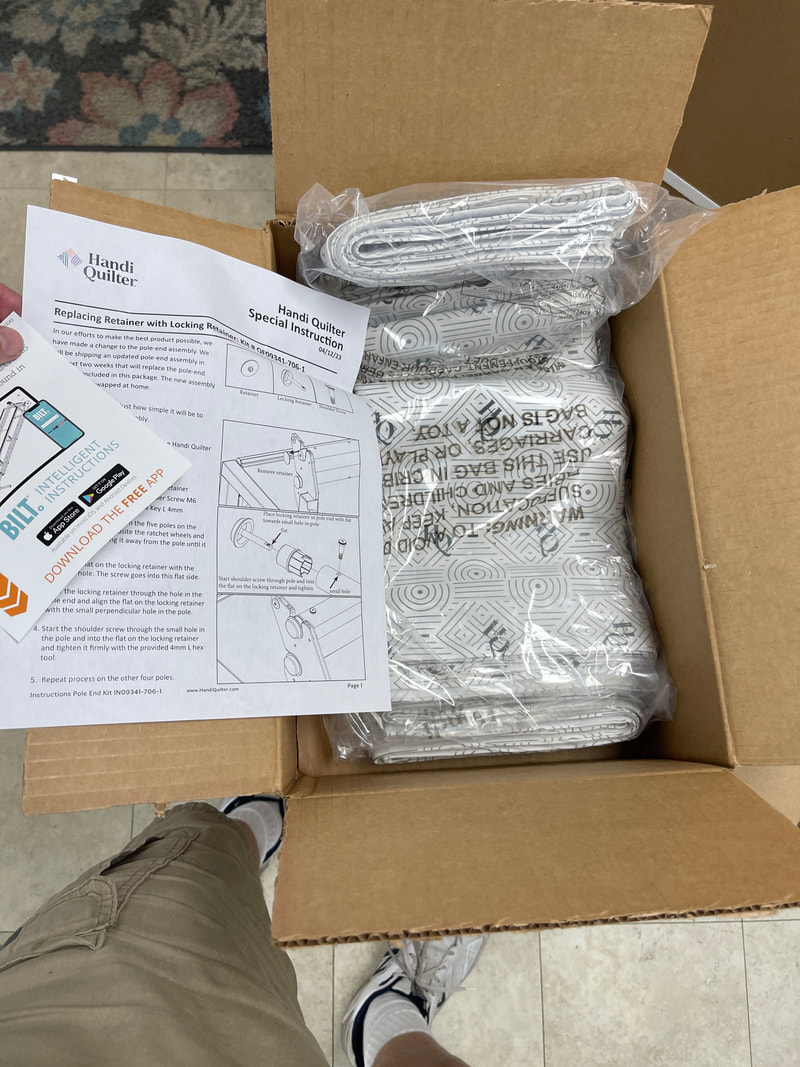

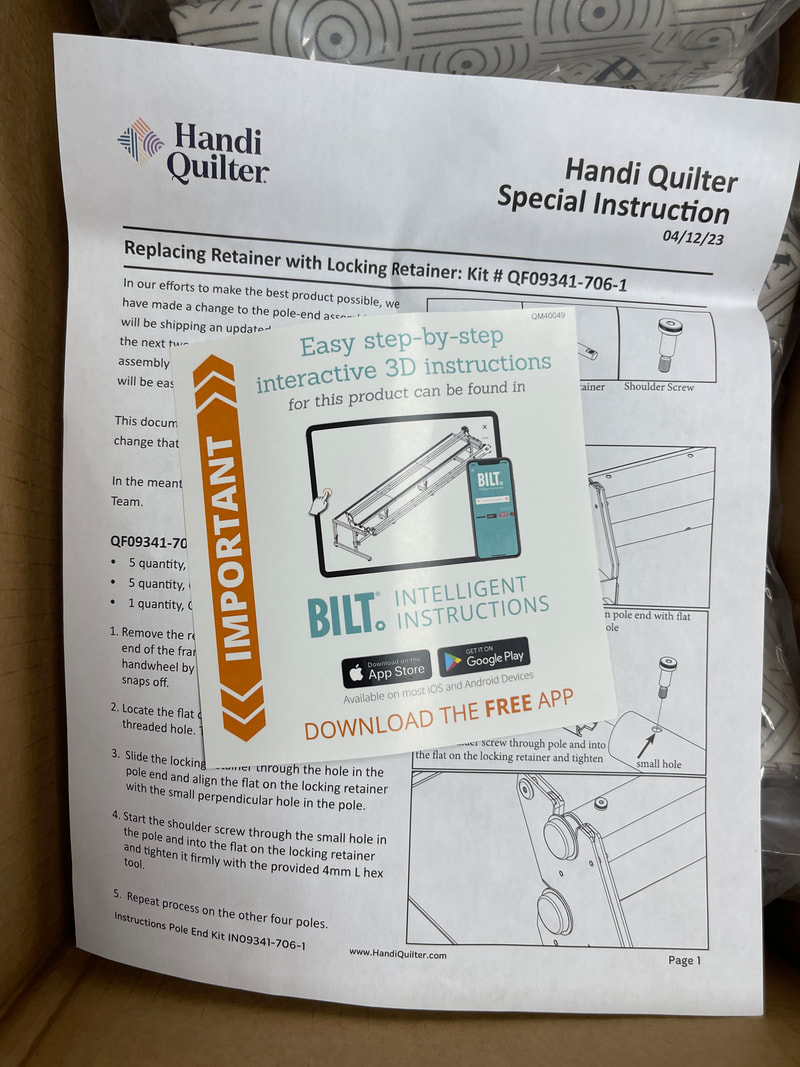

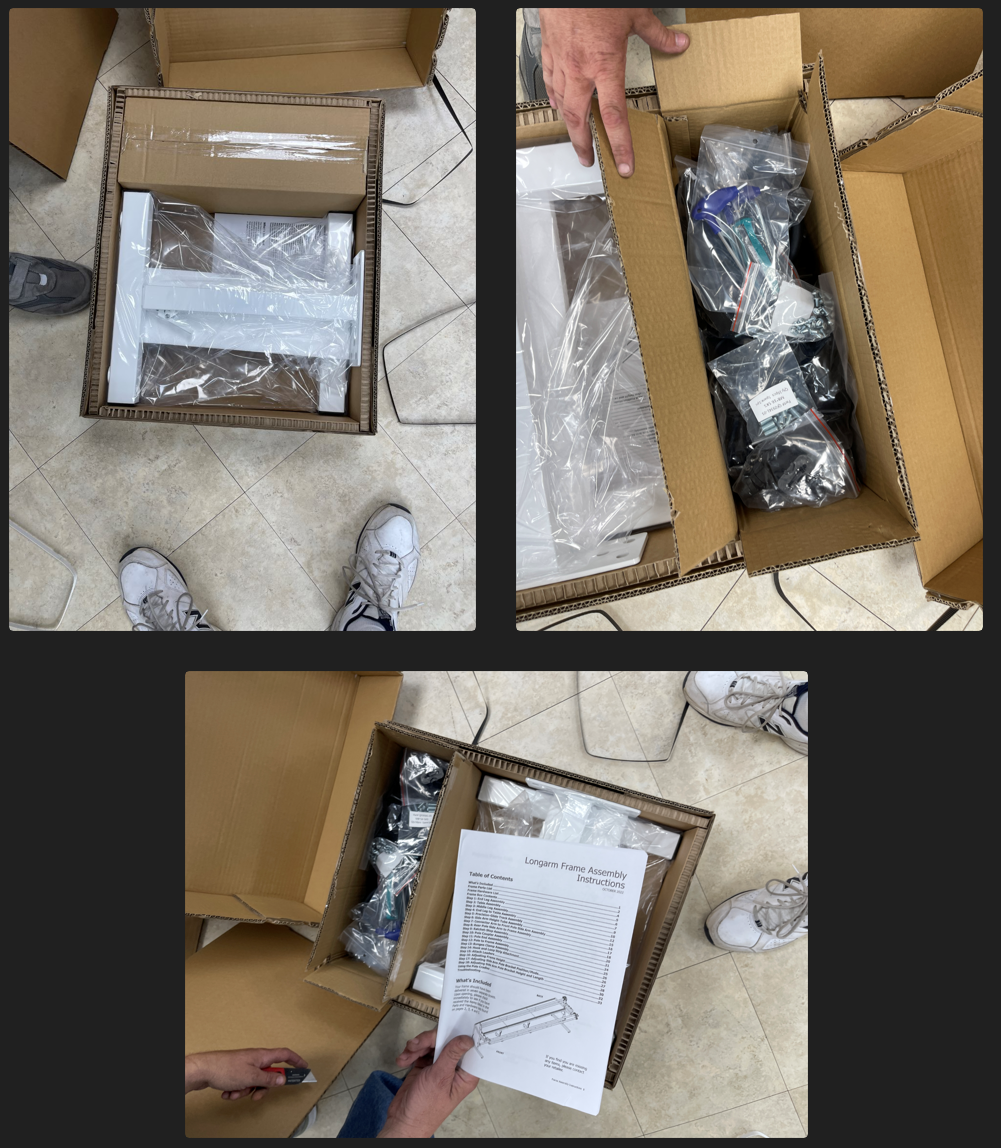

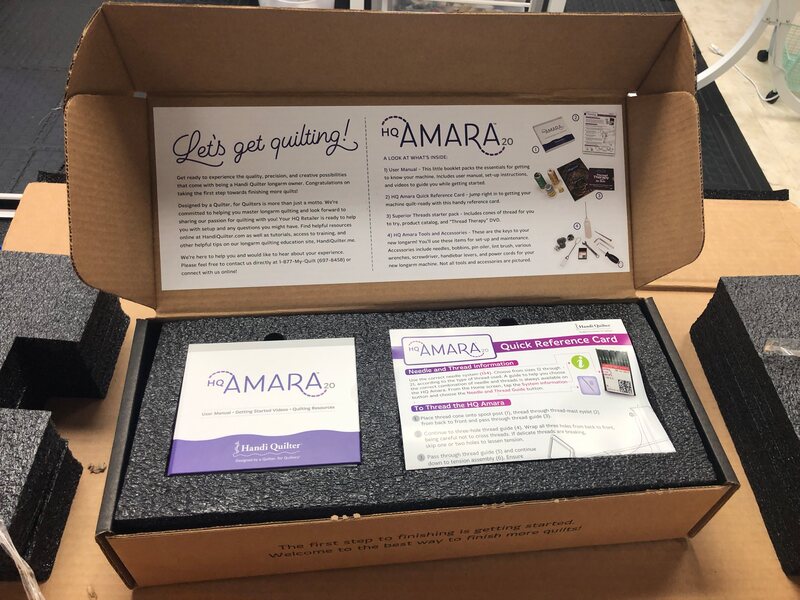

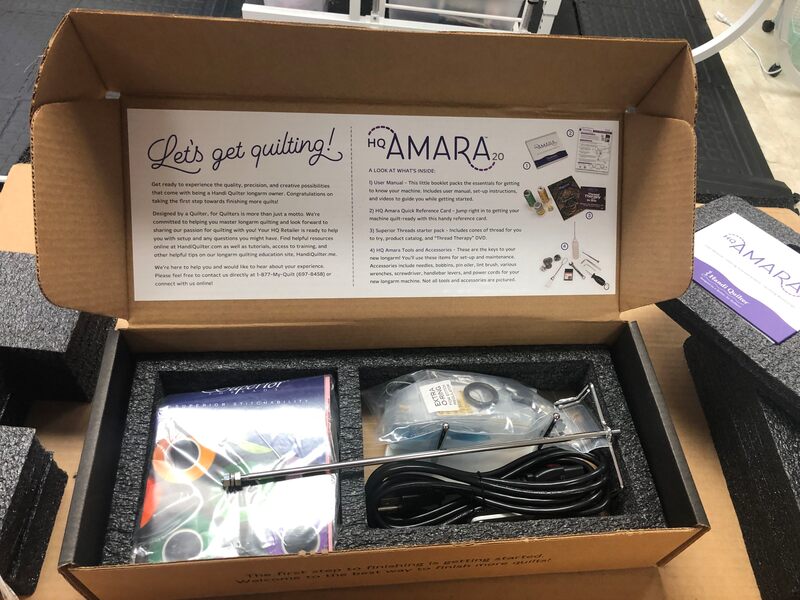

Installation Instructions: The BILT App

If you have a smart phone or tablet running AndroidOS or AppleOS, you can download the app and access the installation instructions in animated format. We used both the animated BILT and the written instructions and still got a few things wrong. The written instruction manual is available in BOX 4. |

|

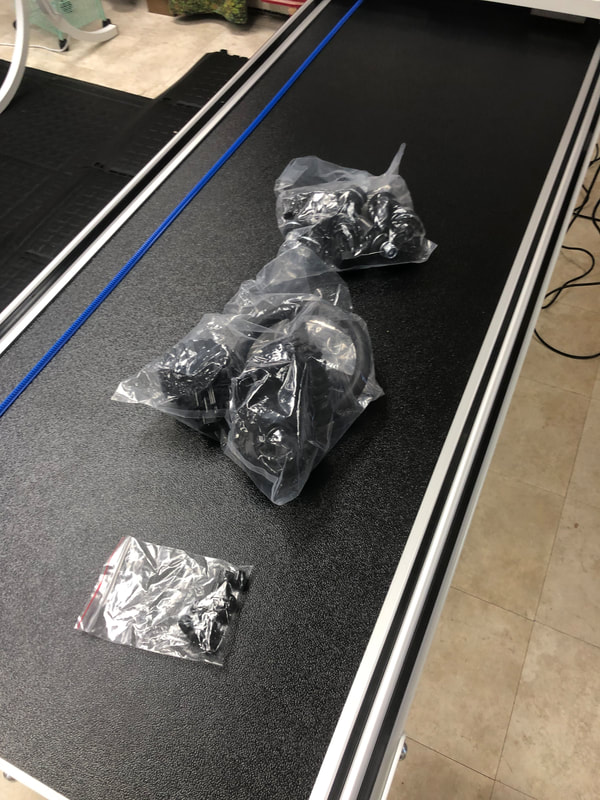

NOBODY TOLD US TO UNBOX EVERYTHING!

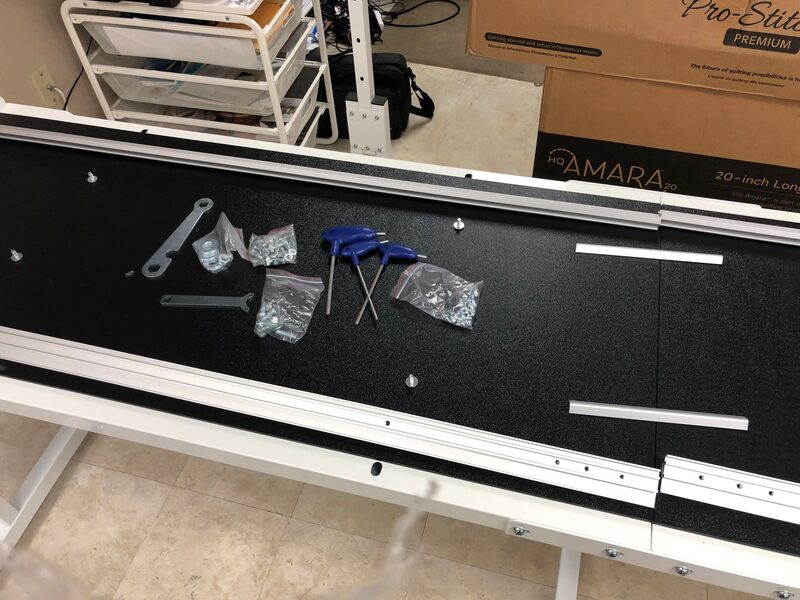

The BILT app starts by telling you to layout parts. So we stopped to unbox everything.

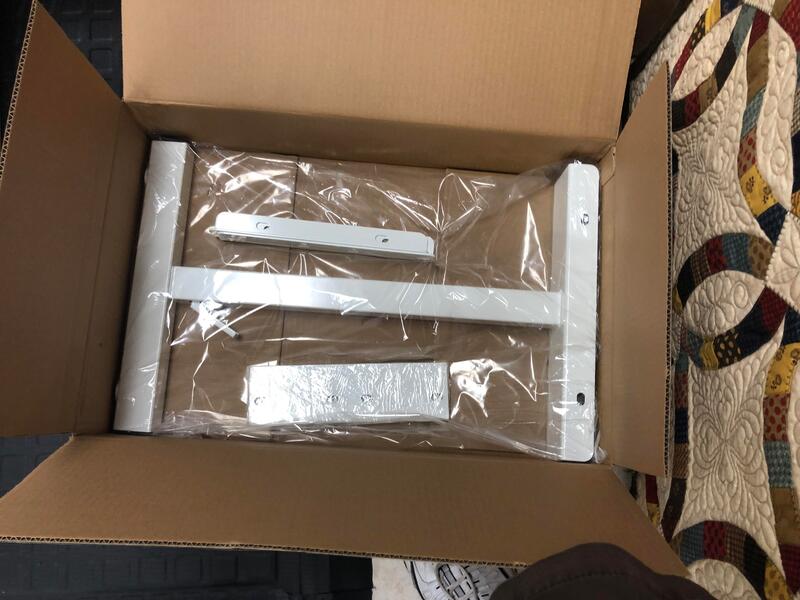

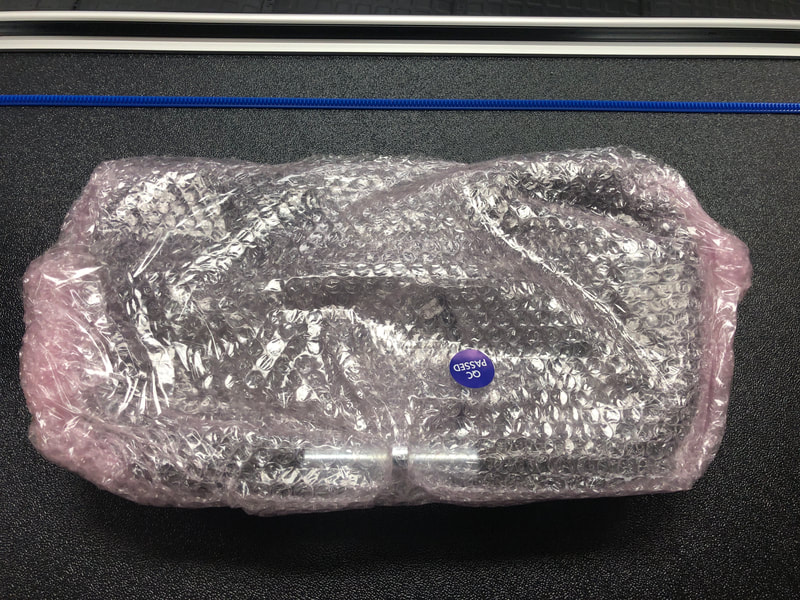

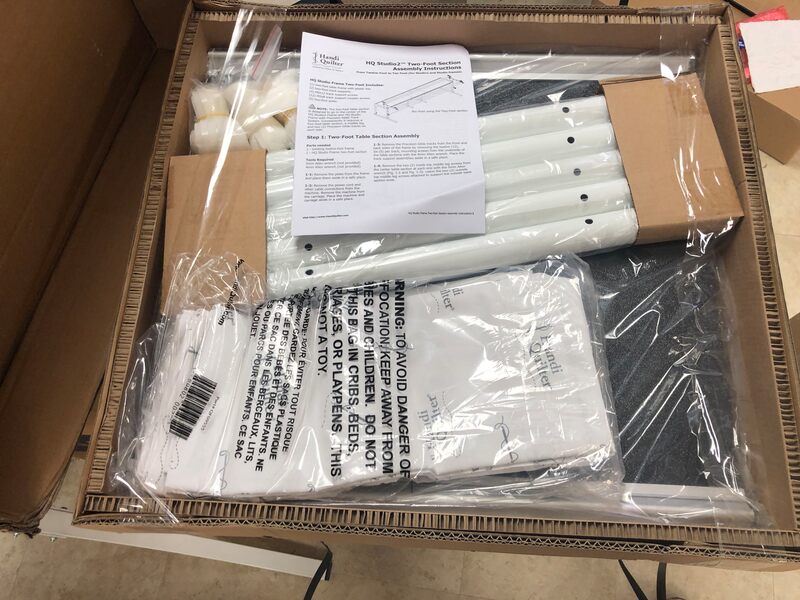

BOX 2 - both of them - contain the 4ft table top and poles. Remove the poles carefully so the cardboard stays on the ends and set them aside. The table sections can be stood against a wall until you need them. |

|

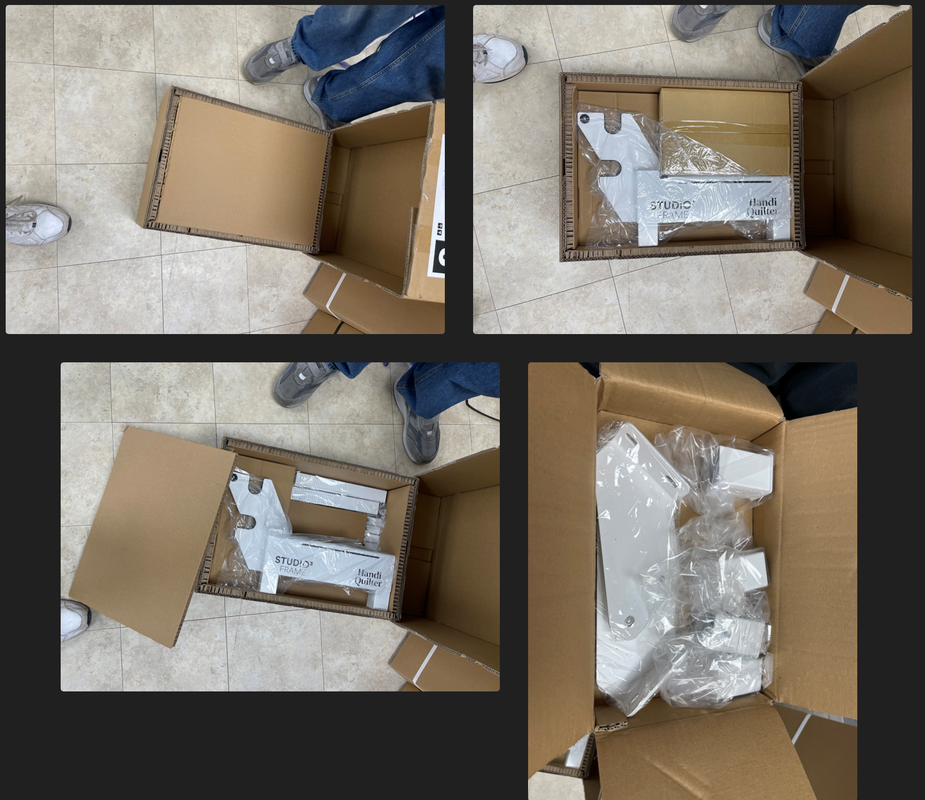

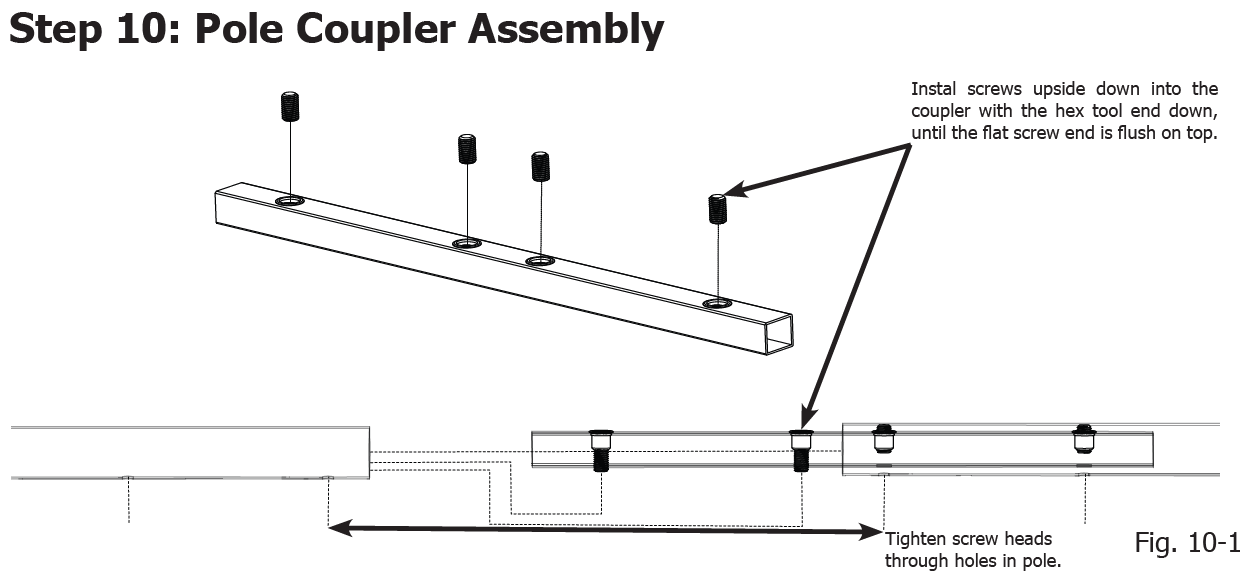

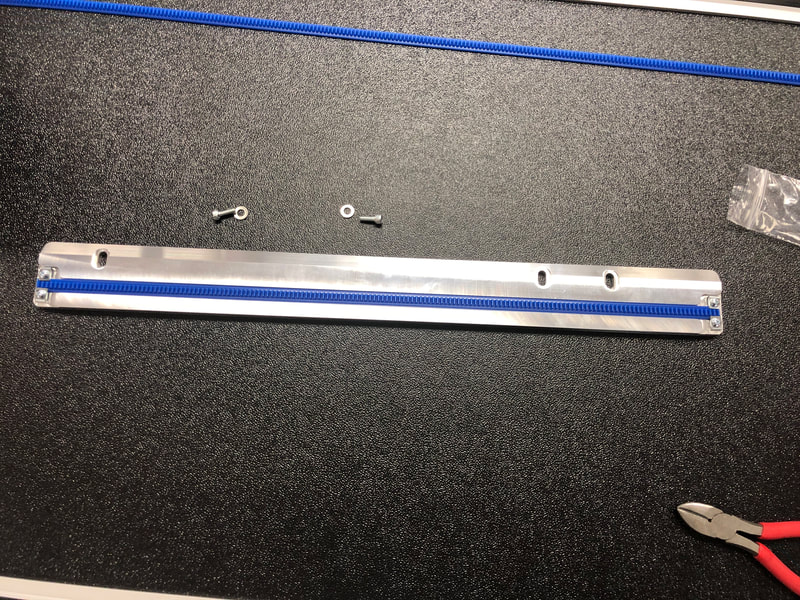

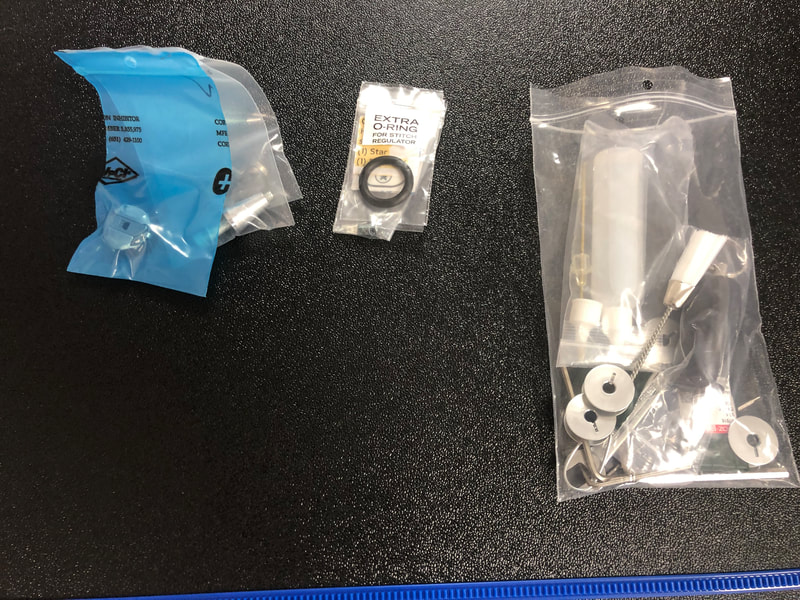

BOX 5: Side arms and related components

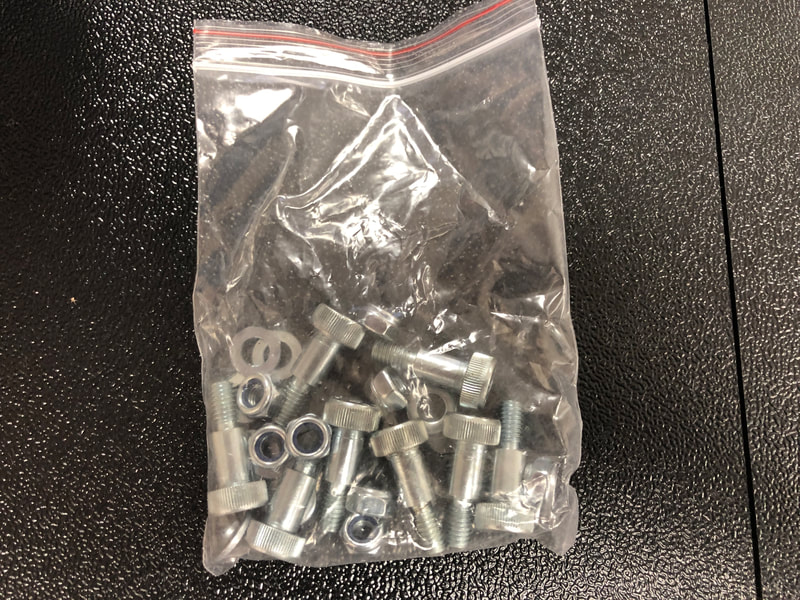

This efficiently packed box has a box in a box with a variety of parts... Table Frame Coupler (qty 4) Pole Coupler (qty 10) Connector Arm - Left (qty 1) Connector Arm - Right (qty 1) Side Arm - Left (qty 1) Side Arm - Right (qty 1) Side Arm - Left Front (qty 1) Side Arm - Right Front (qty 1) Brace, Corner (qty 2) Brace, Corner Mirrored (qty 2) Tube, Side Arm Height (qty 4) The 'pole couplers' are a new engineering marvel that will avoid sagging poles in the future. Nicely done. They are actually square bars with inset screws. |

What confused us?

|

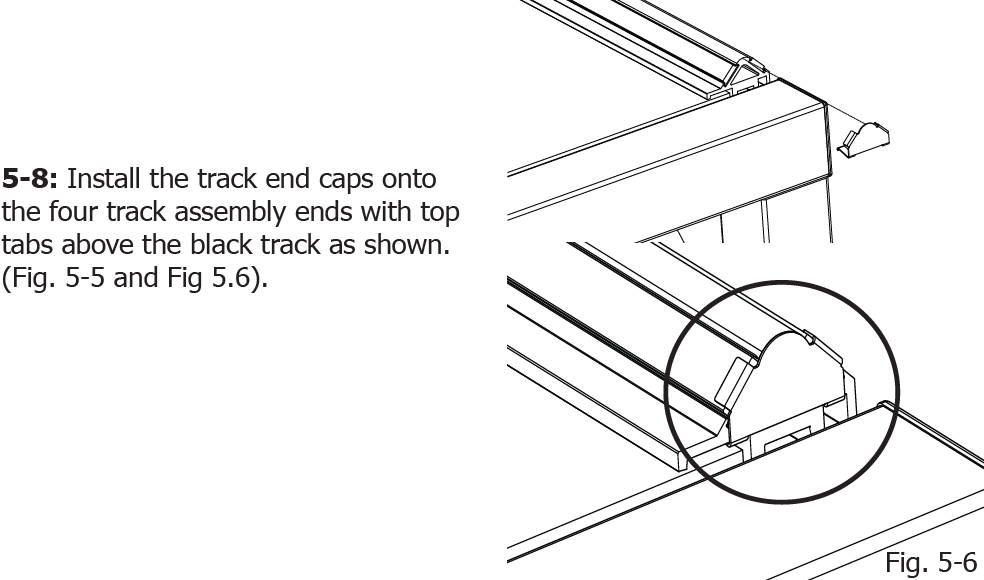

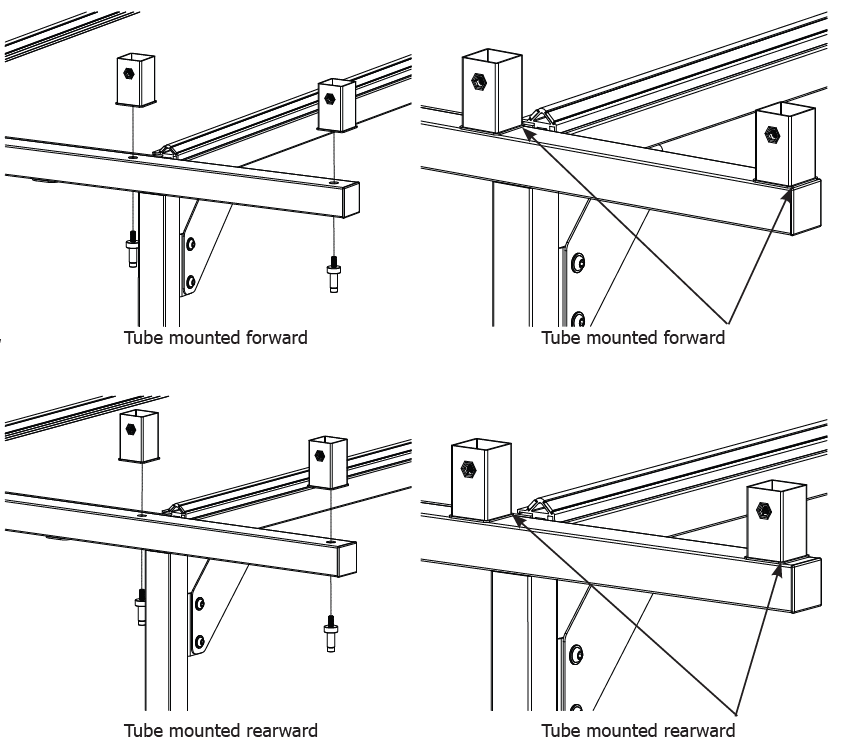

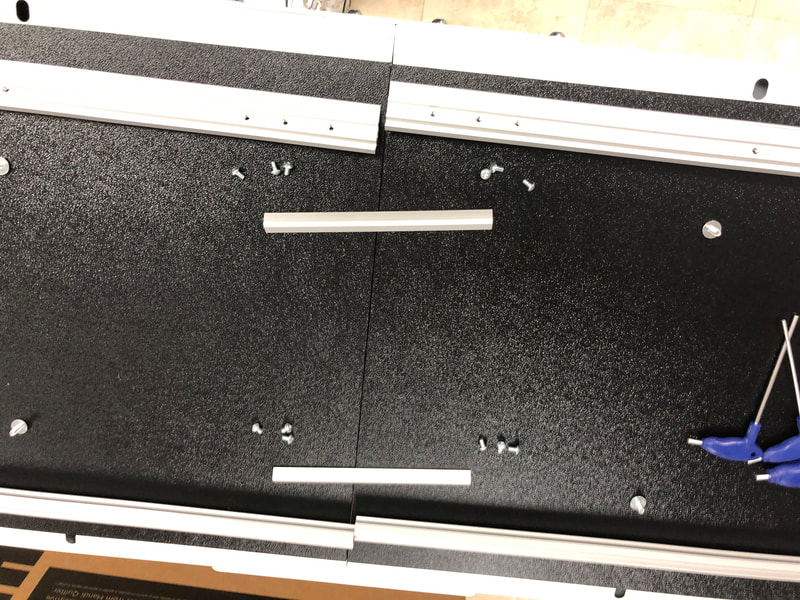

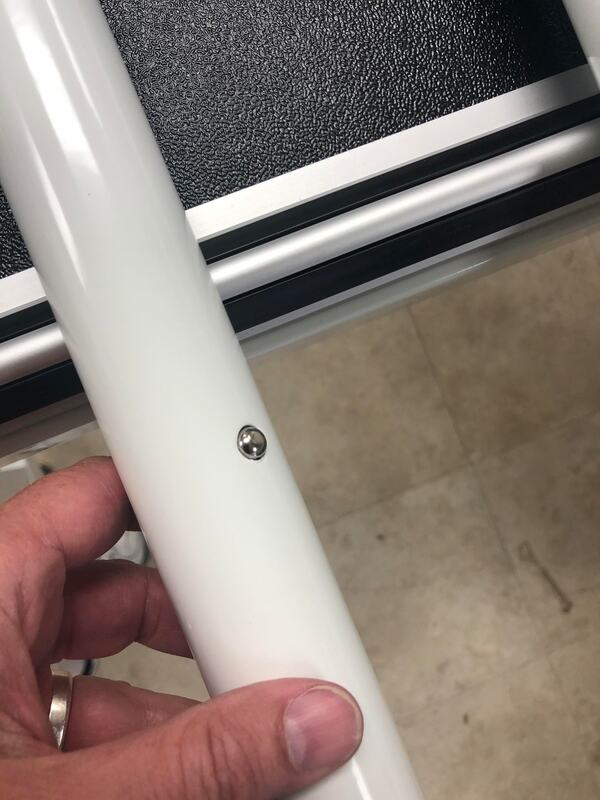

Step 6: Side Arm Height Tube Assembly

6-1: The 20” machine has the height tube mounted rearward. The 16” and 18” machine have the height tube mounted forward. These parts basically move the rear poles back what looks to be half an inch when mounted to the rear. We read that the screw hole should be to the rear and got it wrong the first time. I don't think they could have done any better with the photos in the manual. The BILT instructions used terminology that I was not understanding. |

|

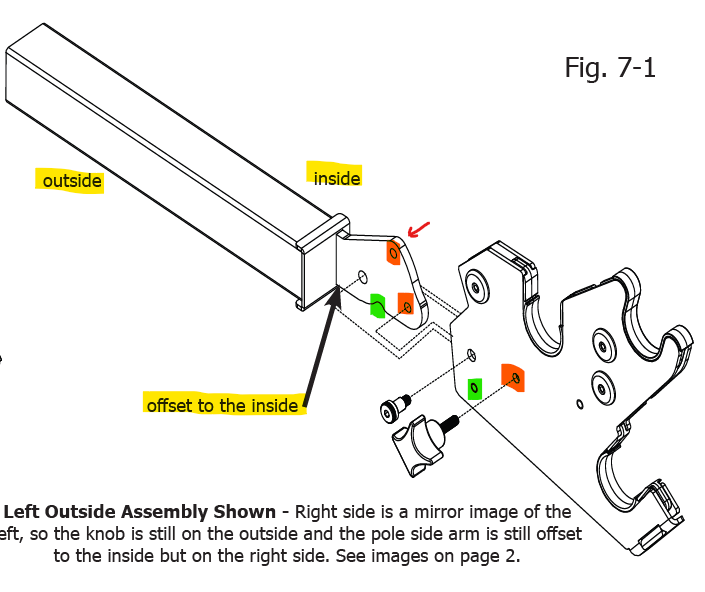

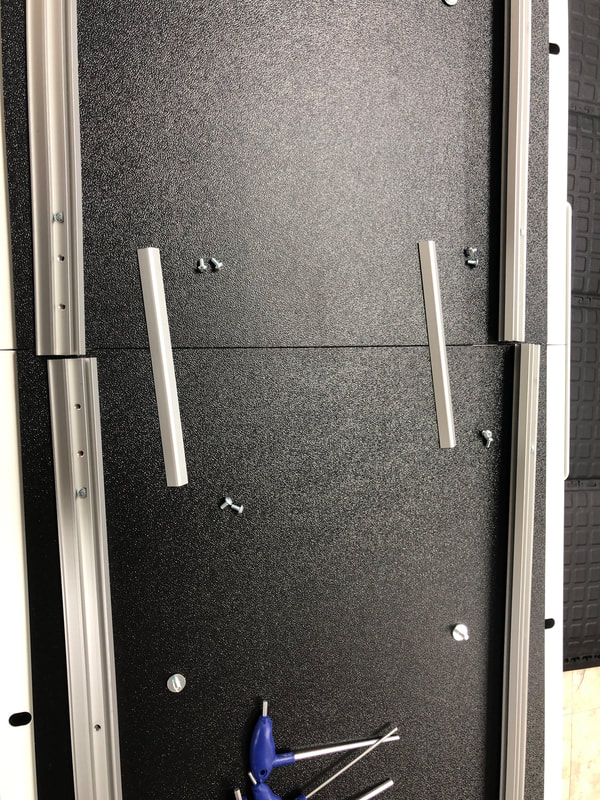

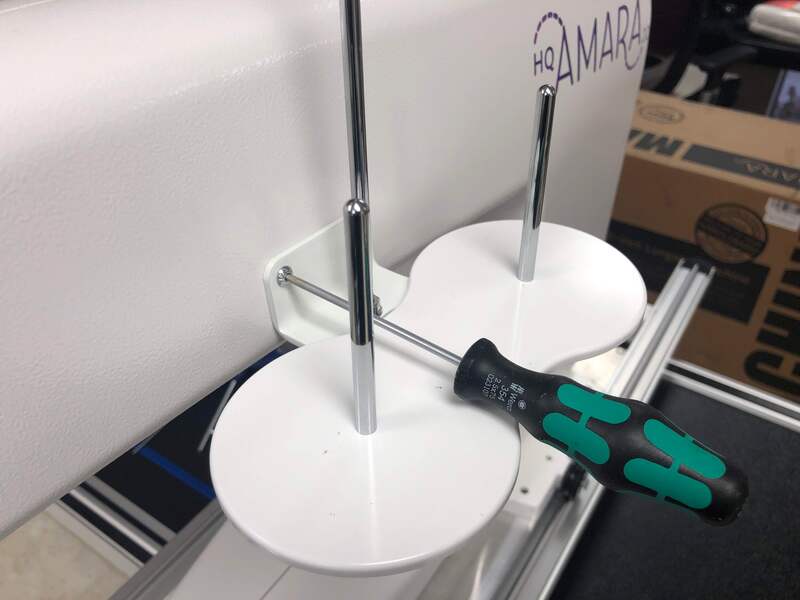

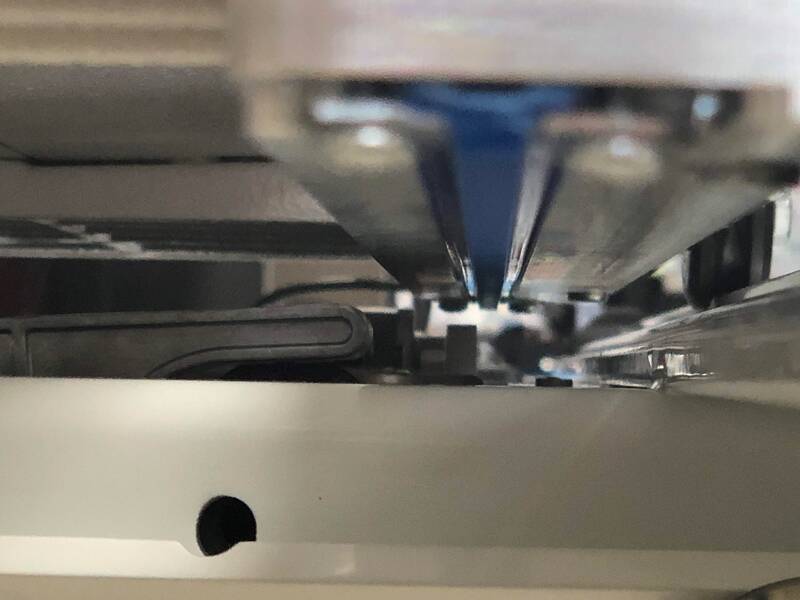

Step 7: Connector Arm to Front Pole Side Arm Assembly

The assembly of the side arms for the Studio3 is much easier to put together than on the Studio2 frame. But here are a few things to look out for... YELLOW: Pay attention to the inside/outside. If you put the bar on the wrong sides of the frame, the poles do not reach. GREEN: The notch on the bottom aligns with a pin that is already inserted into assembly. It acts like a pivot point when changing Clearview modes. RED: If you have ProStitcher, you will want to have the poles in the up position. The new assembly is simpler and more stable. You simply screw in the screw to whichever hole necessary. In this case the TOP hole will give you a standard load. Free motion only machines will likely use the lower Clearview mode. |

What is really nice on the Studio3?

|

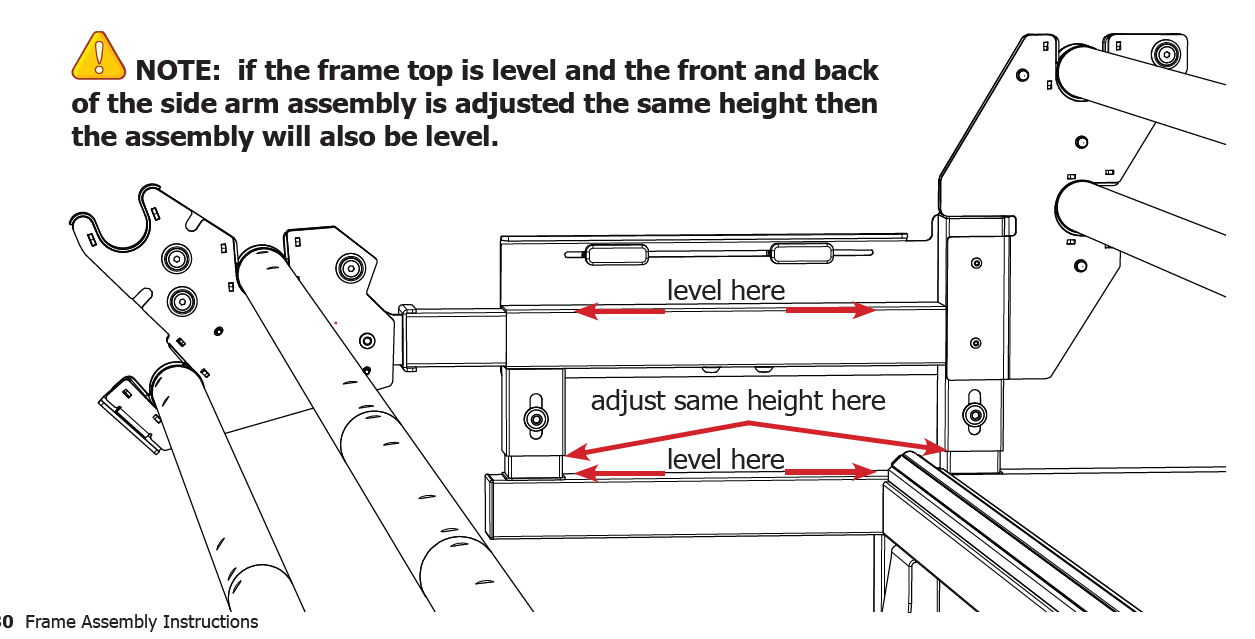

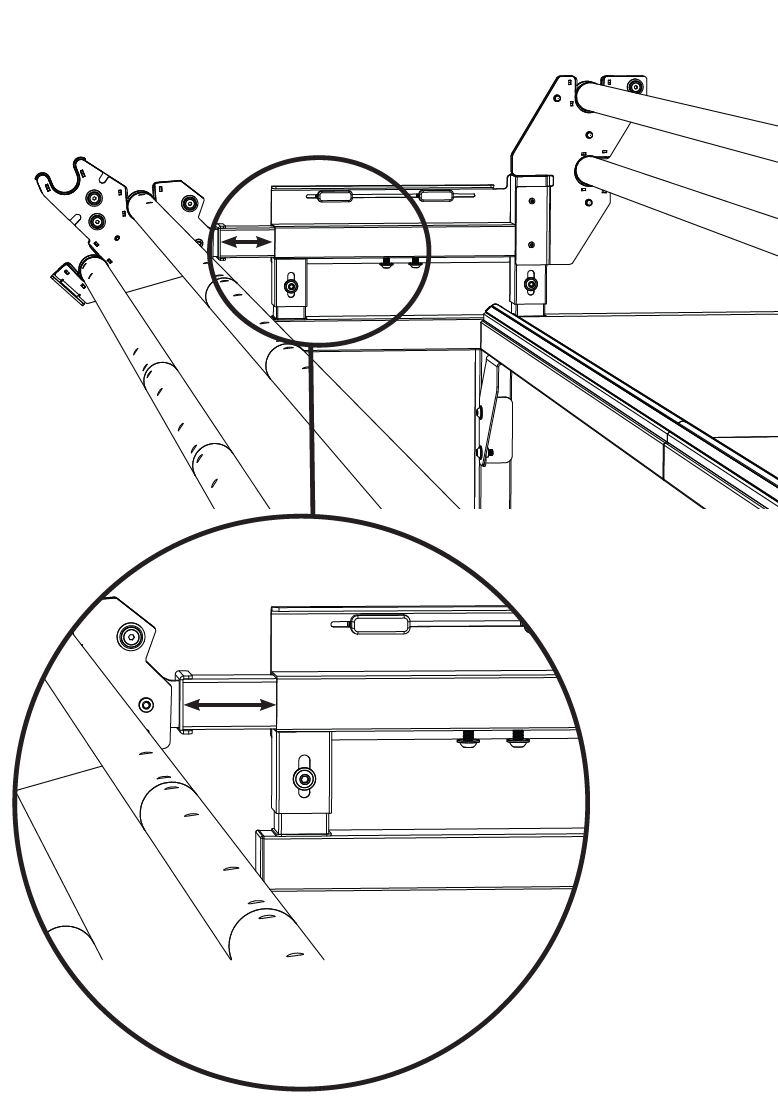

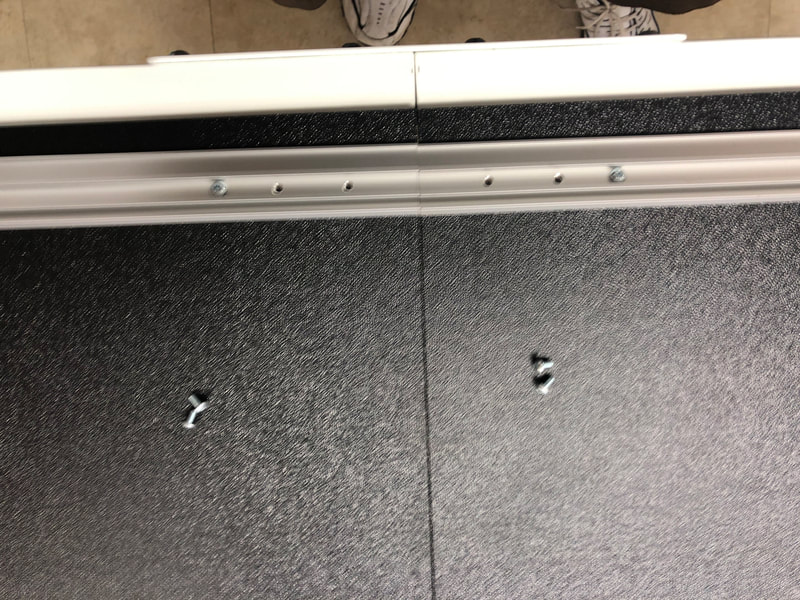

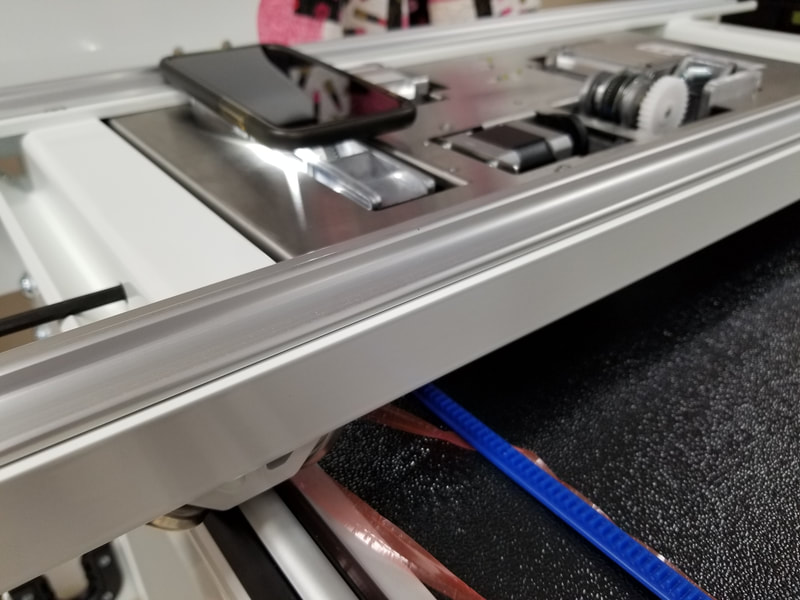

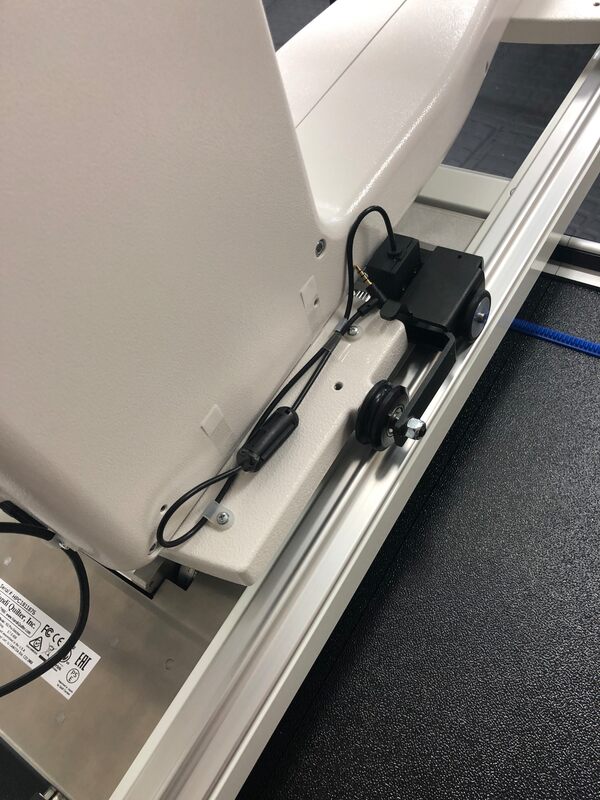

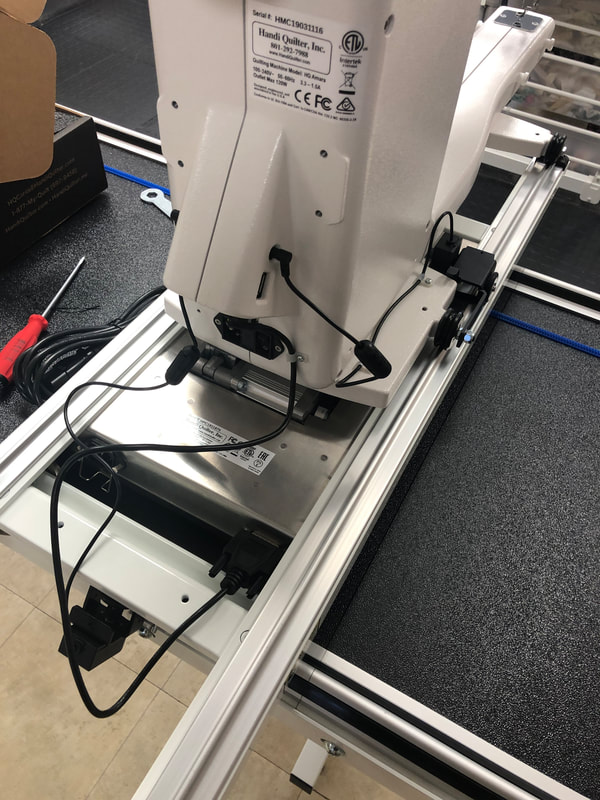

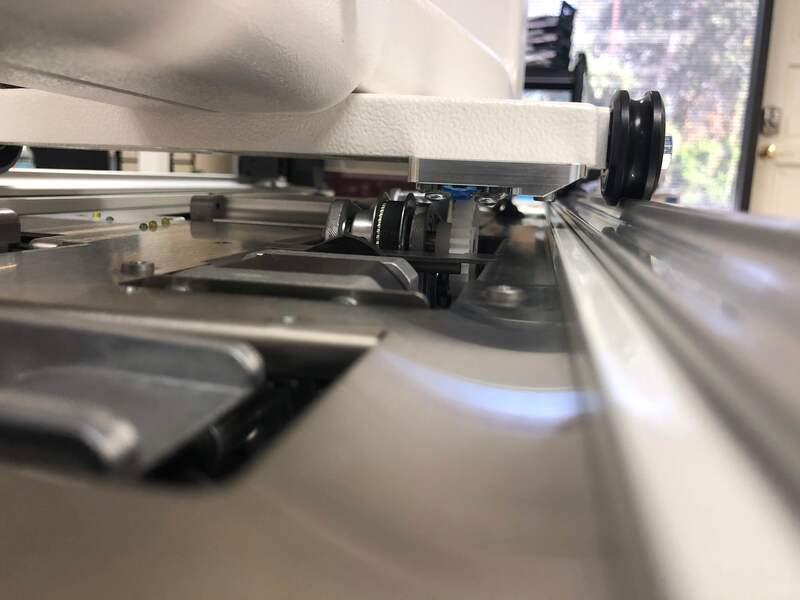

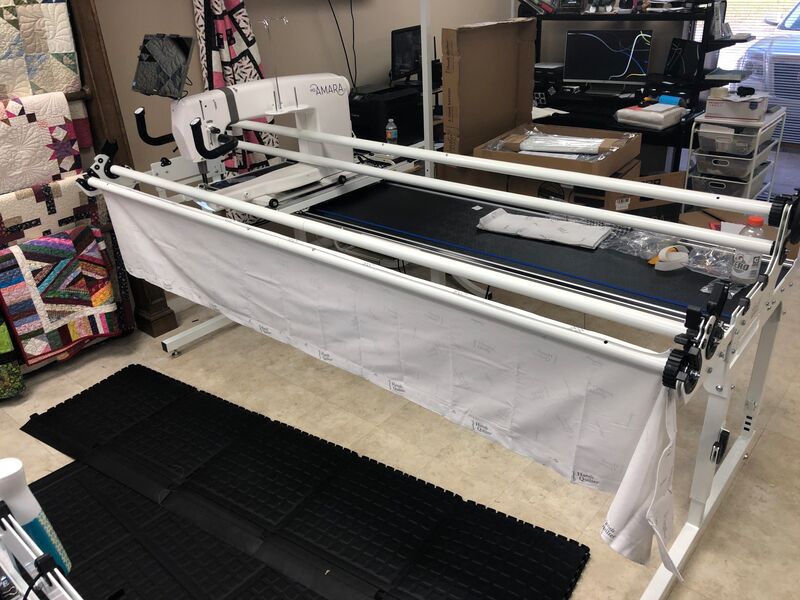

Step 18: Adjusting Side Arm Pole Bracket Height and Length

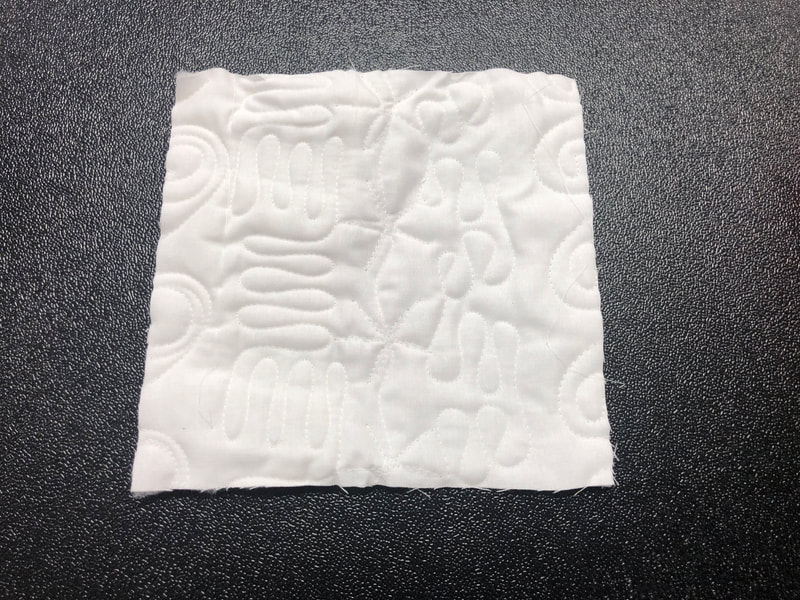

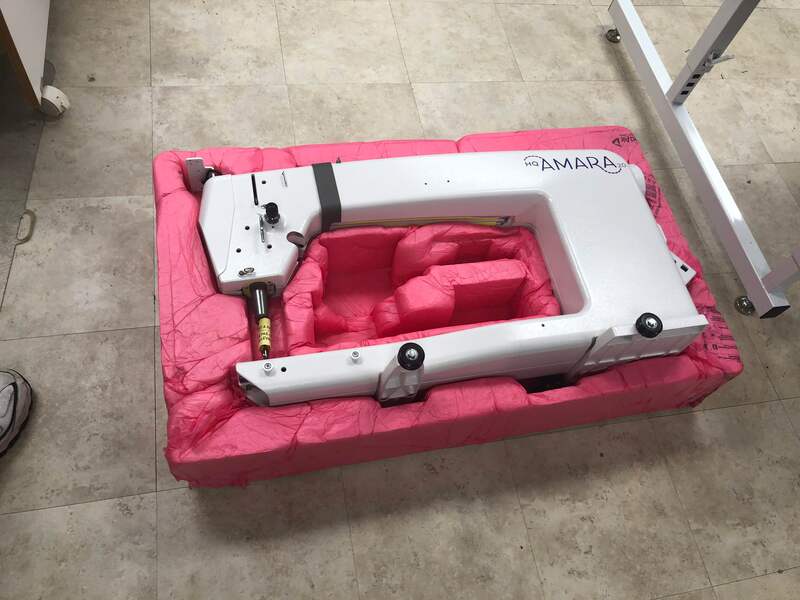

We found the height of the poles to be adequate at the lowest setting (resting) on the side of the frame. This was with a PS carriage and an Amara. The length of the front poles can be adjusted to your preference as long as the needle bar/hopping foot does not hit the front bar before the machine reaches the end of the carriage. Yes - you actually get a half inch of extra usable space compared to the Studio2. The back throat of the machine used to hit just slightly before the wheels would reach the end of the carriage. This is no longer the case. It may be a little less than half an inch, but the ladies were pleased. (You still will have the quilt rolling up and taking away throat space as you go, so plan for it.) |

Picture book of a common installation

Float your mouse over the pictures to read words of wisdom. Click on a picture to enlarge them.

The MKQ Installation Guide supplements the instruction manual and shares tips we have found helpful. This material does not directly pertain to installing a Loft or LittleFoot frame.

|

| ||||||||||||

Note: This Studio2 frame is being set up at only 8ft. This leaves out the middle section of parts. The middle section is either 2ft or 4ft in size, making the 10ft or 12ft frame dimensions. The Amara and Forte are essentially the same machines, but the Forte and Infinity go on the larger Gallery2 frame. All the Gallery parts look similar to the Studio parts.

727-935-1739 = #1 for Studio/Shop - #2 for Support - #3 for Sales

38565 US Highway 19 N - Palm Harbor FL 34684

Shop Hours: Weekdays 10am - 4:30pm. Saturday 10am - 2pm. Closed Sundays.

Quilts Drops should call the Studio for an appointment.

YOUR MACHINE IS ONLY AS GOOD AS YOUR RETAILER

MK Quilts uses all the latest Longarm Quilting Machines with Pro-Stitcher from Handi Quilter

38565 US Highway 19 N - Palm Harbor FL 34684

Shop Hours: Weekdays 10am - 4:30pm. Saturday 10am - 2pm. Closed Sundays.

Quilts Drops should call the Studio for an appointment.

YOUR MACHINE IS ONLY AS GOOD AS YOUR RETAILER

MK Quilts uses all the latest Longarm Quilting Machines with Pro-Stitcher from Handi Quilter